SPP Pumpen

Our customers’ pumping applications are invariably

demanding – typically operating in hostile, arduous or

extreme temperature environments, where quality matters.

Using the most advanced computer testing in the world,

we design, simulate, evaluate, refine and manufacture all

products and packaged systems here in the UK.

Produkte

Eklusiv bei uns erhältlich:

Unistream

CONFIGURATION

Horizontal electric motor

or engine driven

DISCHARGE & PERFORMANCE

• 32 mm to 150 mm

• Outputs up to 504 m3/h

• Heads up to 105 m

FEATURES

• Horizontal DIN 24255 Electric Motor

• 41 models

• Wide choice of materials

• Centreline discharge

• Back pull-out rotating element can be

removed without disturbing pipe work

• Impellers cut to duty

• High interchangeability – just three

shaft modules cover the entire range

• Suitable for baseplate mounting

with coupling

• Approved to LPCB, FM and/or UL

Standards

• In compliance with NFPA 20

• Used in pump as turbine applications

Eurostream

CONFIGURATION

Horizontal electric motor

or engine driven

DISCHARGE & PERFORMANCE

• 32 mm to 150 mm

• Outputs up to 504 m3/h

• Heads up to 105 m

FEATURES

• Horizontal DIN 24255 Electric Motor

• 41 models

• Wide choice of materials

• Centreline discharge

• Back pull-out rotating element can be

removed without disturbing pipe work

• Impellers cut to duty

• High interchangeability – just three

shaft modules cover the entire range

• Suitable for baseplate mounting

with coupling

• Approved to LPCB, FM and/or UL

Standards

• In compliance with NFPA 20

• Used in pump as turbine applications

Instream

CONFIGURATION

Horizontal electric motor

or engine driven

DISCHARGE & PERFORMANCE

• 32 mm to 150 mm

• Outputs up to 504 m3/h

• Heads up to 105 m

FEATURES

• Horizontal DIN 24255 Electric Motor

• 41 models

• Wide choice of materials

• Centreline discharge

• Back pull-out rotating element can be

removed without disturbing pipe work

• Impellers cut to duty

• High interchangeability – just three

shaft modules cover the entire range

• Suitable for baseplate mounting

with coupling

• Approved to LPCB, FM and/or UL

Standards

• In compliance with NFPA 20

• Used in pump as turbine applications

AQUASTREAM –MIXED FLOW

CONFIGURATION

Horizontal or vertical electric motor

or engine driven

DISCHARGE & PERFORMANCE

• 200 mm to 650 mm

• Outputs up to 6480 m3/h

• Heads up to 28 m

FEATURES

• High efficiency pump range

• Mixed flow impeller will handle clean

or dirty water containing small solids

• Heavy duty oil lubricating bearing bracket

• Soft packed

• An excellent range of pump sizes available

• Suitable for baseplate mounting with

coupling

KPD

CONFIGURATION

Horizontal or vertical electric or engine

driven process pump

DISCHARGE & PERFORMANCE

• Delivery up to 200 mm

• Outputs up to 900 m3/h

• Heads up to 225 m

FEATURES

• Back pull-out arrangement

• Bearing oil cooling arrangement

• Steam jacket arrangement

• Centre line mounting

• Mechanical seal or gland packed

• Temperatures range -50 to 350 °C

GK

CONFIGURATION

Horizontal, electric motor

DISCHARGE & PERFORMANCE

• Delivery up to 100 mm

• Outputs up to 800 m3/h

• Heads up to 140 m

FEATURES

• Back pull-out

• ISO 5199 / 2858 / EN:22858

• Enclosed impeller only

• Gland packed

• Balanced impeller

• Top centre line discharge

• No venting required

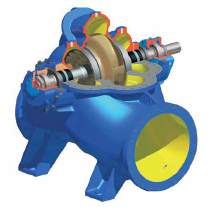

LLC

CONFIGURATION

Horizontal, vertical open shaft,

vertical direct mounted electric

motor or horizontal engine driven

DISCHARGE & PERFORMANCE

• 125 mm to 600 mm

• Outputs to 9000 m3/h

• Heads up to 300 m

FEATURES

• Axially split casing – rotating element can

be removed without disturbing pipework

• Exceptional hydraulic efficiencies

• Double and single entry back to back

impellers reduce end thrust, increase

efficiency and bearing life

• Modular design for maximum

interchangeability. Multiple impeller

selections

• Stainless steel impellers and shaft as

standard

• Internal high efficiency coating as

standard

• Cartridge mechanical seals as standard

• Double row thrust bearing

• Wide operating range and extended

bearing life

• Reduced efficiency degradation

• Approved to FM and/or UL standards

• In compliance with NFPA 20

• Used in pump as turbine applications

HYDROSTREAM

CONFIGURATION

Horizontal, vertical open shaft,

vertical direct mounted electric

motor or horizontal engine driven

DISCHARGE & PERFORMANCE

• 25 mm to 600 mm

• Outputs to 9000 m3/h

• Heads up to 275 m

FEATURES

• Axially split casing – rotating element can

be removed without disturbing pipework

• High hydraulic efficiencies

• Double and single entry back to back

impellers reduce end thrust, increase

efficiency and bearing life. Shaft sleeves

are standard

• 62 models. Module design for maximum

interchangeability. Multiple impeller

selections

• Wide choice of materials

• Grease or oil lubrication

• Soft packing or mechanical seals

• API options available for off site

applications

• Approved to FM and/or UL standards

• In compliance with NFPA 20

THRUSTREAM

CONFIGURATION

Horizontal, vertical open shaft,

vertical direct mounted electric motor or

horizontal electric motor or engine driven

DISCHARGE & PERFORMANCE

• 65 mm to 350 mm

• Outputs up to 3500 m3/h

• Heads up to 300 m

FEATURES

• Axially split casing – rotating element can

be removed without disturbing pipework

• High hydraulic efficiencies

• Double entry impellers reduce end thrust,

increase efficiency and bearing life

• Shaft sleeves fitted as standard for soft

packed pumps and as an alternative for

mechanical seals. Stainless steel shafts

fitted as standard for mechanical seals

• 40 models. Module design for maximum

interchangeability

• Grease lubrication

• Soft packing or mechanical seals

• Suitable for baseplate mounting with

coupling

• Approved to LPCB, FM and/or UL

standards

• In compliance with NFPA 20

UP

CONFIGURATION

Horizontally axially split casing, single

stage, double or single suction, single or

double volute with horizontal shaft

DISCHARGE & PERFORMANCE

• Delivery up to 1200 mm

• Outputs up to 24,120 m3/h

• Head up to 180 m

FEATURES

• Rotating assembly accessible for

inspection or maintenance by removing

upper half casing without disturbing

suction and delivery piping and motor

• Horizontal execution (standard) or vertical

execution (optional)

• Vertical pump, direct drive or with

universal shaft arrangement

• High hydraulic and overall efficiency due

to superior design and manufacturing

techniques

• Good suction performance and low NPSH

• Stable characteristics, minimum

maintenance required, vibration free

performance

• High reliability

• Mechanical seal or gland packed

• 50 or 60 hz operation

CF

CONFIGURATION

Multi-stage pump with modular

construction

DISCHARGE & PERFORMANCE

• Delivery size up to 50 mm

• Outputs up to 20 m3/h

• Head up to 315 m

• Temp up to 120 °C

FEATURES

• Channel multi-stage, Modular Construction

• Gland Packed / Mechanical Seal

• Electrical Drive / Engine Drive

• Self priming

• Conforming to DIN 24254

SHM

CONFIGURATION

Horizontal non-clog pumps having single

stage, single suction with back pull out

type design

DISCHARGE & PERFORMANCE

• Delivery up to 200 mm

• Outputs up to 800 m3/h

• Head up to 90 m

FEATURES

• Back pull-out design

• Solids handling up to 105 mm

• Impeller type non clog

• Oil or grease lubricated bearing housing

• Mechanical seal or gland packed

• Temp up to 140 °C

SHL

CONFIGURATION

Horizontal and vertical single stage solids

handling pump

DISCHARGE & PERFORMANCE

• Delivery up to 900 mm

• Outputs 13,000 m3/h

• Heads up to 82 m

FEATURES

• Solids handling up to 300 mm

• Mechanical seal or gland packed

• Impeller enclosed or semi open type

• Grease or oil lubrication

• Available in various materials

SHS

CONFIGURATION

Vertical non-clog pumps for wet pit

applications, these pumps can be offered

with a column length up to 6.5 m

DISCHARGE & PERFORMANCE

• Delivery up to 300 mm

• Outputs up to 800 m3/h

• Head up to 90 m

FEATURES

• Solids handling up to 105 mm

• Mechanical seal or gland packed

• Available in various materials

• Impeller non clog type

• The pump unit is suspended by a

column pipe which also protects the

transmission shaft.

FREEWAY

CONFIGURATION

Vertical direct mounted or open shaft

electric motor driven

DISCHARGE & PERFORMANCE

• 75 mm to 600 mm

• Outputs up to 4320 m3/h

• Heads up to 100 m

FEATURES

• Separate pump and motor

• Pump rotating element incorporation

bearing and seal arrangement

• Hydraulic loads taken by pump bearing

assembly, not motor bearings

• Double cartridge mechanical seal option

• Hydraulic design – low specific speed

designs

• Bespoke wear liner

• Large solids passing capacity

• Hardened metallic impeller option

• Positively locked impeller

FREESTREAM

CONFIGURATION

Horizontal, vertical open shaft, vertical

direct mounted

DISCHARGE & PERFORMANCE

• Delivery up to 200 mm

• Outputs up to 1080 m3/h

• Heads up to 90 m

FEATURES

• High efficiency spiral vane impeller

designed to handle large solids, thick

sludges and fibrous materials

• Impeller cut to specific duty

• Modular construction to maximise

interchangeability

• Steep H/Q curves mean that changes in

pumping head can be tolerated without

significant loss of efficiency

• Soft packing or mechanical seals

Ihr Partner für Pumpen

Kostenlose Beratung

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.